Home » Keywords: » inspection

Items Tagged with 'inspection'

ARTICLES

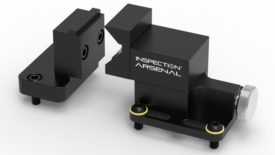

Featured Product from Phillips Precision

Introducing the Spanner-Vise™ V-Jaws

October 1, 2023

Speaking of Quality | John Vandenbemden

Auditing vs. Inspection

Even though there are similarities, these tools have different intent.

May 17, 2023

Quality Headline

ASQ Houston, Inspection Division Conference Coming in September

August 25, 2022

Quality 101

Fixturing 101: Crucial For Quality

Inspection data is critical to delivering perfect parts faster, experts say.

May 8, 2022

In-line Inspection with CMMs

By increasing the frequency of inspections and decreasing the time of inspection throughout the production process, inspecting in or near the production line allows for verification of 100% of components.

May 3, 2022

Test & Inspection

The Journey to Creating an Inspection Standard

The scope of inspection is so vast that no one wanted to exclude a topic, but we also did not want a standard so detailed that it was not user friendly.

May 1, 2022

Why In-Line Inspection Can Save Time and Money

To simplify and hasten the measurement process, manufacturers are bringing measurement to the production line for verification, minimizing the time needed to refine machining.

February 14, 2022

NDT | Trends

Monitoring Assets with Restricted Access Phased Array

Corrosion is complex, and mitigating and managing it is not a linear process.

August 15, 2021

EVENTS

Webinar

11/10/22 to 11/10/23

Contact: Meg M.

Reduce the Complexity of Your CNC CMM Programming Tasks

Webinar

2/28/23 to 2/28/24

Contact: Meg M.

2023 Life Sciences Quality Trends: How Digital Transformation Is Advancing Quality Management

Webinar

3/29/23 to 3/29/24

Contact: Meg M.

Top Tech Trends to Watch in Vision-Guided Robotics Technology

Webinar

9/13/23 to 9/13/24

Contact: Meg M.

How to Reduce First Article Inspection Creation Time by 70-90%

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SUBSCRIBE TODAY!Copyright ©2023. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing